Vacuum Forming / Thermoforming Services

Turn flat plastic sheets into custom 3D shapes — fast, accurate, and scalable.

Turn flat plastic sheets into custom 3D shapes — fast, accurate, and scalable.

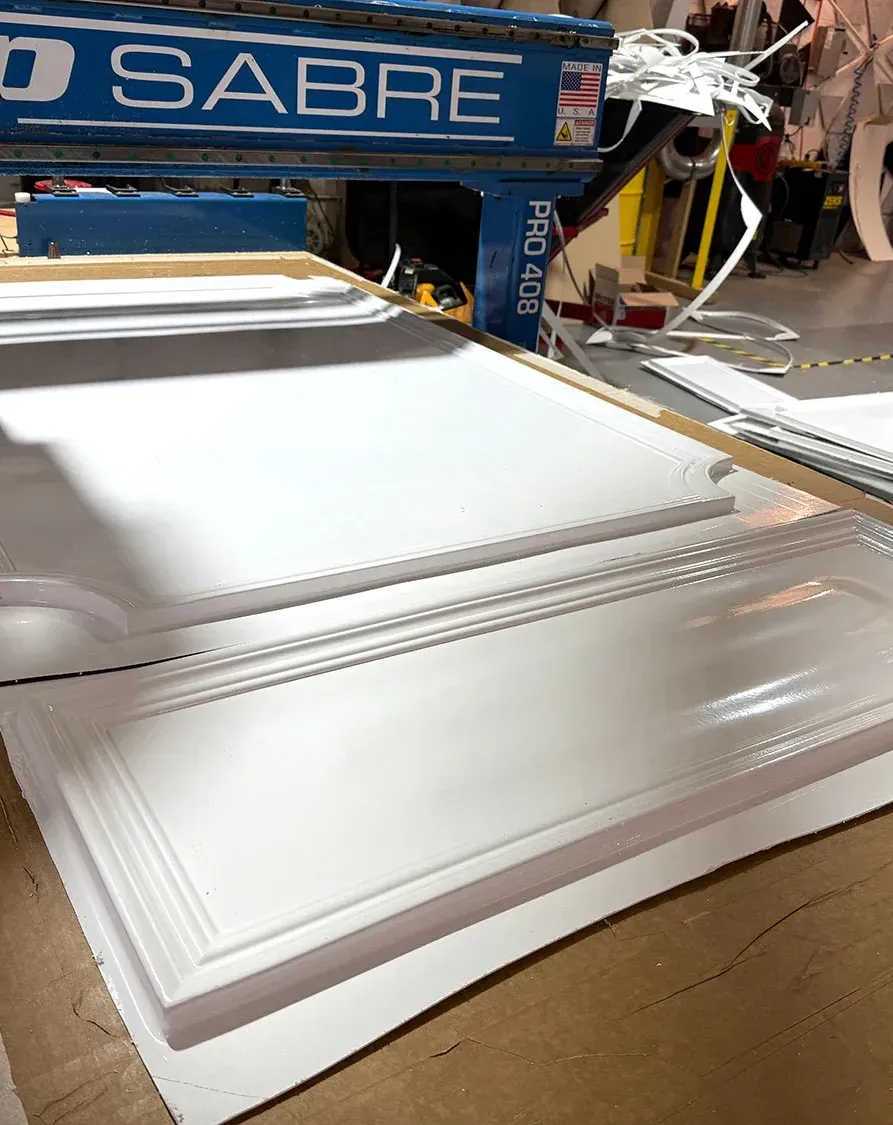

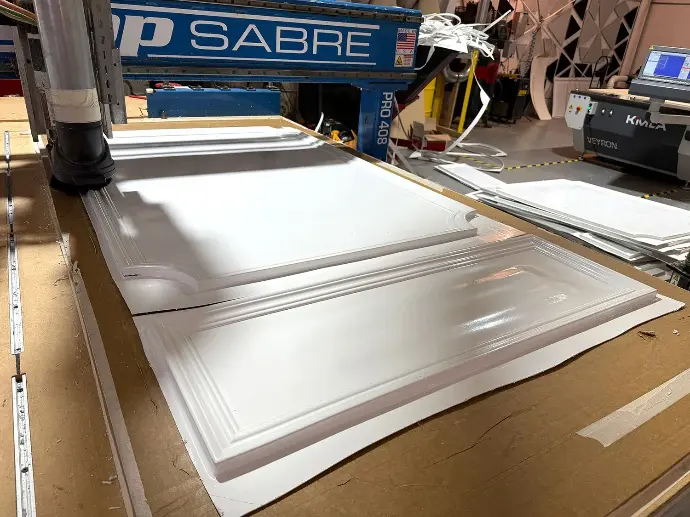

At 865FabLab, our vacuum forming service enables you to take plastic sheets and transform them into contoured parts, covers, trays, enclosures, signage elements, and more. We combine material knowledge, tooling, and thermal forming expertise to deliver reliable results for prototypes and production runs.

What We Offer

- Sheet-fed vacuum forming of thermoplastics (ABS, acrylic, PETG, PVC, etc.)

- Deep draws and moderate contours (up to ~22 inches in depth)

- Pneumatic clamping and adjustable frames for clean edges

- Precision heating control (infrared radiant panels, percentage heat control)

- High-vacuum performance with surge tank for stable forming

- Tooling support: plug assists, draft angles, venting

- Finishing, trimming, flange trimming, and secondary processing

Typical Specs & Capabilities

- Max sheet size: 48″ × 96″ (122 × 244 cm)

- Depth of draw (max): up to about 22 inches (55 cm)

- Material gauges supported: up to ¼ inch (0.64 cm)

- Clamping frame: fully adjustable, pneumatic drive (~300 lb seal pressure) (belovac.com)

- Heating system: Infrared radiant heater with “percentage control” (0–100%) and “size-down” capability

- Vacuum / pump system: High-volume vacuum with onboard surge tank (often 40+ gallon)

- Control & automation options: Programmable heating timers, optional PLC control, multi-zone heating capability

Process Overview

Submit your design or 3D model, or ask us to assist with tool design

Choose material & thickness based on part needs

We build or source tooling (mold, plug assist, decking)

Sheet heating, stretching, and vacuum forming

Trim and finish to final geometry

Pickup or ship — including protection and packaging

Ideal Applications

Enclosures, housings, and covers

Trays, inserts, bins, and packaging

POP/retail display shells

Clamshells, blister dials, faceplates

Architectural decorative elements

Prototyping complex plastic forms

Vacuum Forming FAQ's

Yes — we can form parts with depths up to ~22 inches depending on material and tooling.

We accommodate materials up to about ¼ inch thickness, depending on the plastic type, tooling, and part geometry.

Yes — we can either work with customer-supplied molds or create tooling in-house depending on the project.

Lead times depend on part complexity, tooling needs, and volume — often between a few days to a week for prototyping runs.

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.