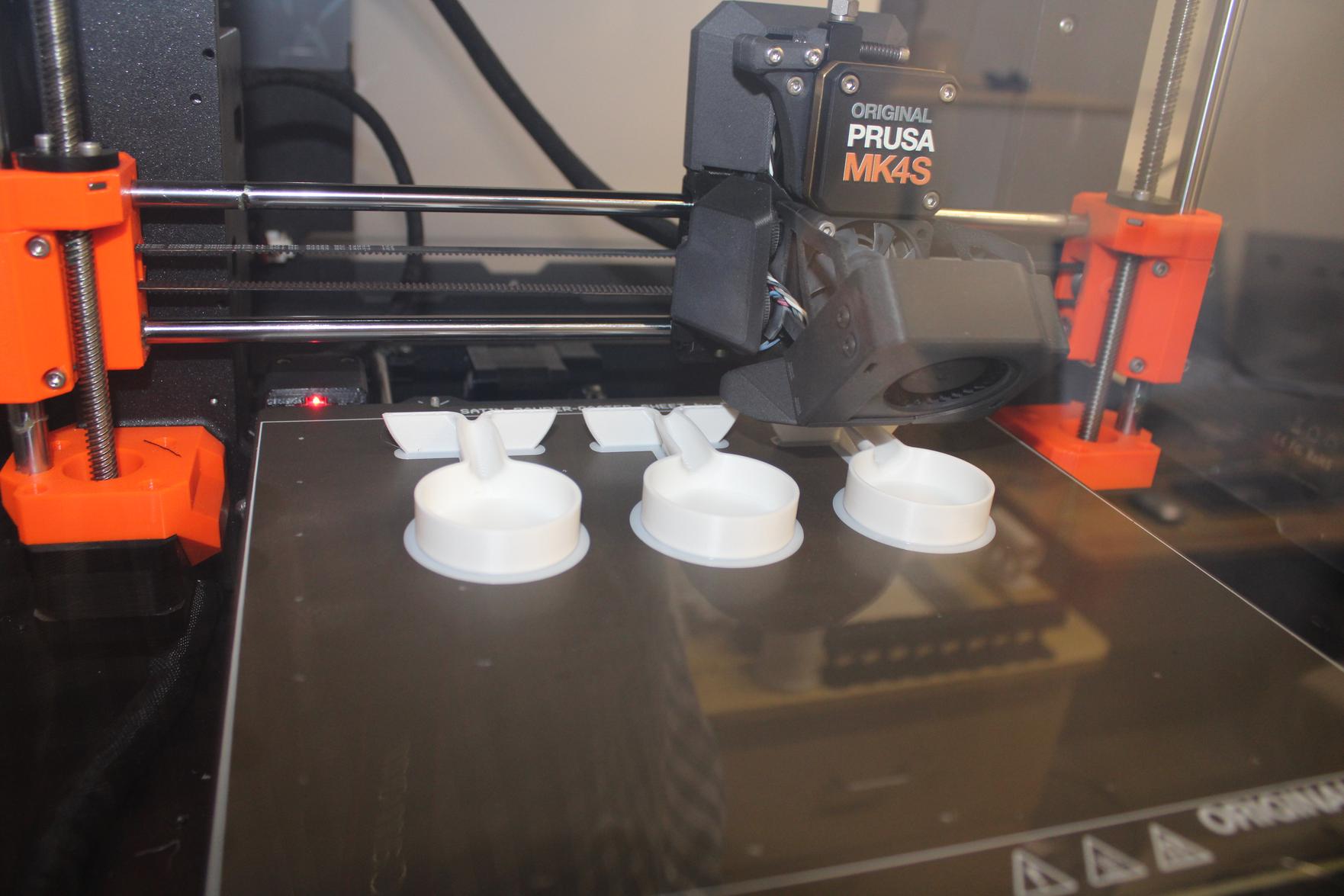

3D Printing Services / Print Farm

Full-color, multi-material, multi-head 3D printing with flexibility and speed

Full-color, multi-material, multi-head 3D printing with flexibility and speed

At 865FabLab, our 3D printing farm is engineered to deliver high-throughput, multi-material parts using a combination of tool‑changing and single‑extruder systems. We can support complex parts, color differentiation, and multiple material combinations in a single print job — or scale with parallel production runs across machines.

Our Setup & Capabilities

- Multi-head tool changer unit supports up to five independent extruders for multi-color or multi-material prints in a single build

- CoreXY mechanics for faster, smooth motion

- Large build volumes for bigger parts or assemblies

- Multiple single-extruder units in parallel for high output of simpler parts

- Support for standard filament materials like PLA, PETG, ABS, TPU, and specialty blends

- Automatic calibration & leveling ensures reliable first layers and consistent output

- Networked print farm workflow for remote monitoring, job scheduling, and batch management

Workflow & Process

- Submit your 3D model file (STL, STEP, OBJ, etc.)

- Discuss material requirements and multi-material strategies

- We optimize the job across print heads or machines

- Print & monitor through our farm management system

- Post-processing — support removal, sanding, assembly, etc.

- Ship or pick up, packaged and ready to integrate

Typical Print Specifications

Parameter Typical Performance Build volume (multi-head) ~360 × 360 × 360 mm (or equivalent “large-cube” envelope) (Prusa3D by Josef Prusa) Extruder count Up to 5 heads for simultaneous material/color printing (Prusa3D by Josef Prusa) Print resolution ~0.1 mm (100 µm) to ~0.3 mm (300 µm) depending on model and use case Filament diameter 1.75 mm Material types PLA, PETG, ABS, TPU, engineering blends, composites.

Ideal Use Cases

Functional prototype parts needing multi-material structure

Enclosures, housings, brackets, and interfaces

Custom jigs, tooling, fixturing, and aligners

Model parts with embedded multi-color detail or gradients

Low-run parts or custom one-offs where cost, speed, and complexity matter

Batches of simpler parts produced in parallel on single-extruder units

Materials & Material Strategies

We can print with a variety of filament materials, and combine them intelligently in a single print:

Rigid plastics: PLA, PETG, ABS, ASA

Flexible / elastomeric: TPU, TPE

Composite & specialty blends: carbon-fiber, glass-filled, etc.

Support materials / internal scaffolding: dissolvable or breakaway supports

Multi-color and multi-material builds using tool-changer head(s)

With our multi-head system, we can assign different materials or colors to individual sections of your model, or craft infill/support strategies that use alternate materials for ease of removal.

3D Printing FAQ's

Yes — using our multi-head tool-changing printer, we can combine rigid, flexible, or composite materials within a single build.

We can print parts up to the envelope of our largest multi-head machine (typically ~360 × 360 × 360 mm). Larger parts can be split and assembled.

Yes — simpler parts may run concurrently on our fleet of single-extruder units. This helps reduce queue times and increases throughput.

We accept STL, OBJ, STEP/IGES, 3MF, and other standard 3D formats. We also assist with file cleanup and slicing optimization.

Yes — we offer support removal, sanding, priming, minor assembly, and batching services as needed.

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.