Foam Cutting Services

Giant foam letters, custom logos, and sculpted props — cut cleanly and at scale.

Giant foam letters, custom logos, and sculpted props — cut cleanly and at scale.

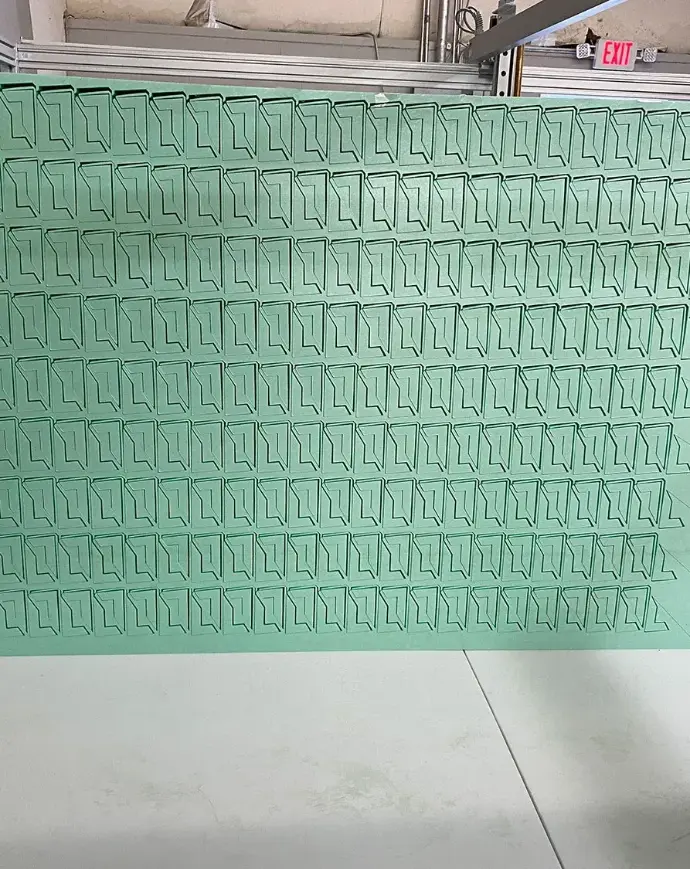

At 865FabLab, we specialize in advanced hot wire foam cutting for signage, packaging, architectural molds, and large-scale props. Our production-grade machine can operate with up to 10 hot wires simultaneously, allowing for efficient, high-volume foam processing — from giant foam letters to custom foam packaging inserts.

Foams We Cut

Ideal for Hot Wire Cutting

Expanded Polystyrene (EPS)

Extruded Polystyrene (XPS)

Polyethylene (PE) / Ethafoam (with caution)

Expanded Polypropylene (EPP) (case-by-case)

Not Suitable for Hot Wire

Polyurethane (PU) — toxic fumes

EVA Foam — sticky residue, poor cut quality

Spray Foam — safety hazard when heated

We only cut foams proven to perform cleanly and safely on a hot wire system.

Cutting Capabilities

Multi-wire hot wire foam cutting with up to 10 active wires at once

Max cutting size: Up to two foam buns (4' × 4' × 8') processed simultaneously

Contour and profile cutting with bevels, arcs, and radius details

Precision-cut 3D foam logos and sculptural forms

Clean, sealed-edge cutting with minimal mess or dust

EPS mold production for precast or cast-in-place concrete

High-speed output for repetitive parts or multi-cut layouts

Our Applications

- Giant Foam Letters — perfect for malls, photo ops, and activations

- Foam Sculptures & Props — for trade shows, themed spaces, and marketing displays

- Custom Foam Logos — dimensional branding elements for exhibitions or retail

- EPS Molds for Concrete — durable forms for architectural or specialty concrete

- Foam Inserts & Packaging — for fragile items, drones, tech gear, and military cases

- 3D Display Builds — assembled pieces for set design, backdrops, and structures

- Moss Wall Displays - We fabricate custom foam structures as a lightweight base for preserved or artificial moss walls — perfect for branded installations, green-themed displays, and scenic environments.

Finish Options

Hardcoating — for reusability and outdoor durability

Paint, Branding & Graphics — custom-finished to your spec

Multi-part Assembly — joinery for oversized or complex builds

Rubber Foam Add-ons — for packaging or cushioned support

Hybrid Construction — combine foam with Re-board or PET acoustic panels

Foam Cutting FAQ's

Yes. We regularly produce giant foam letters, foam logos, and sculptural props for events, retail spaces, and exhibitions. These can be hard coated, painted, and branded.

We can cut up to two foam buns (4' × 4' × 8') at the same time — ideal for both oversized parts and high-output batch runs.

We cut EPS, XPS, PE, and EPP foams. We do not cut polyurethane, EVA, or spray foam due to health and quality risks.

Yes — our machine supports up to 10 hot wires running in parallel, allowing us to produce multiple identical parts in a single pass.

Absolutely. We fabricate custom EPS molds for architectural casting, precast panels, and other concrete forming applications.

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.