CNC Laser Cutting & Engraving

Precision cutting, engraving, and etching for a wide range of materials

Precision cutting, engraving, and etching for a wide range of materials

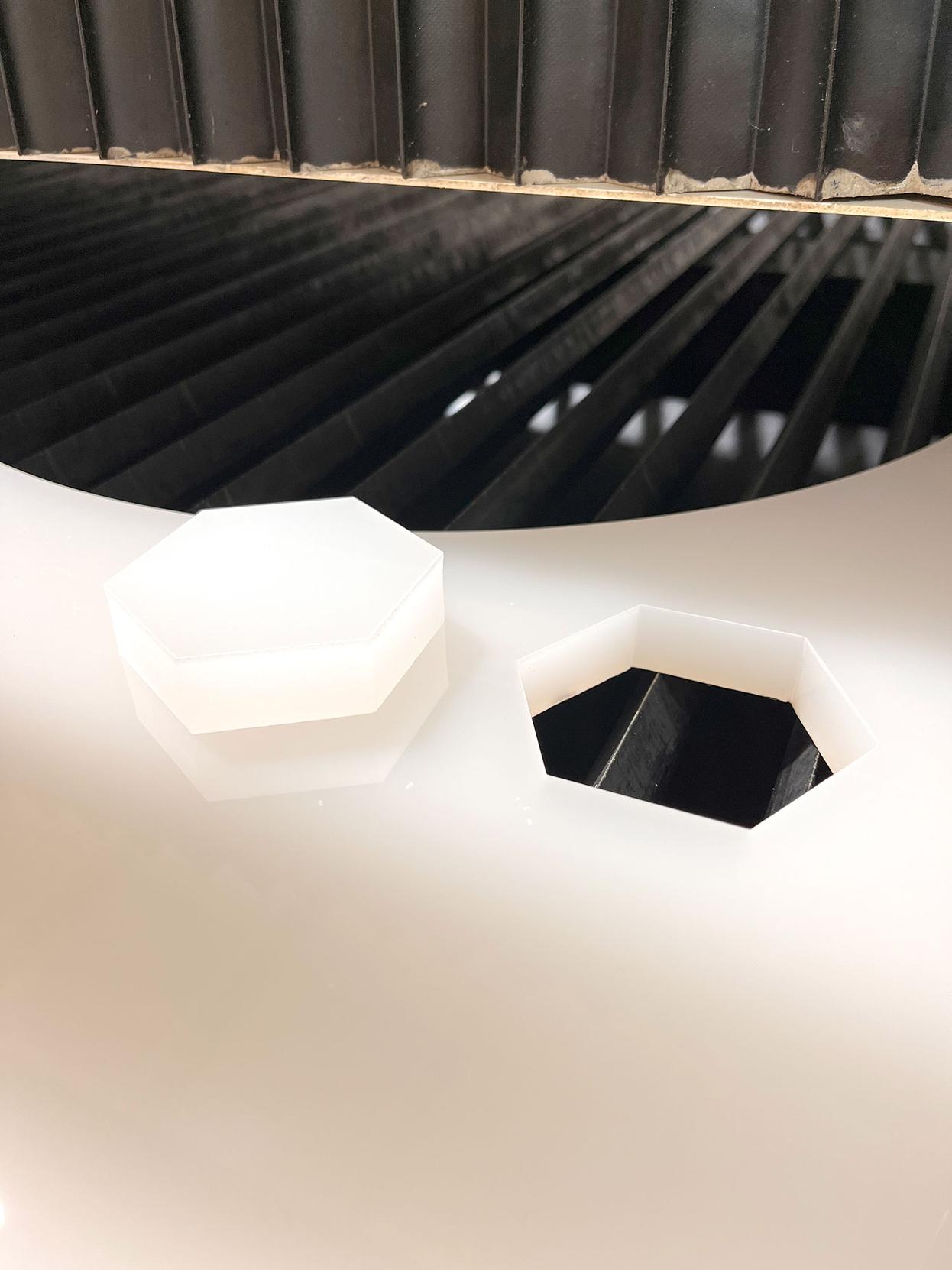

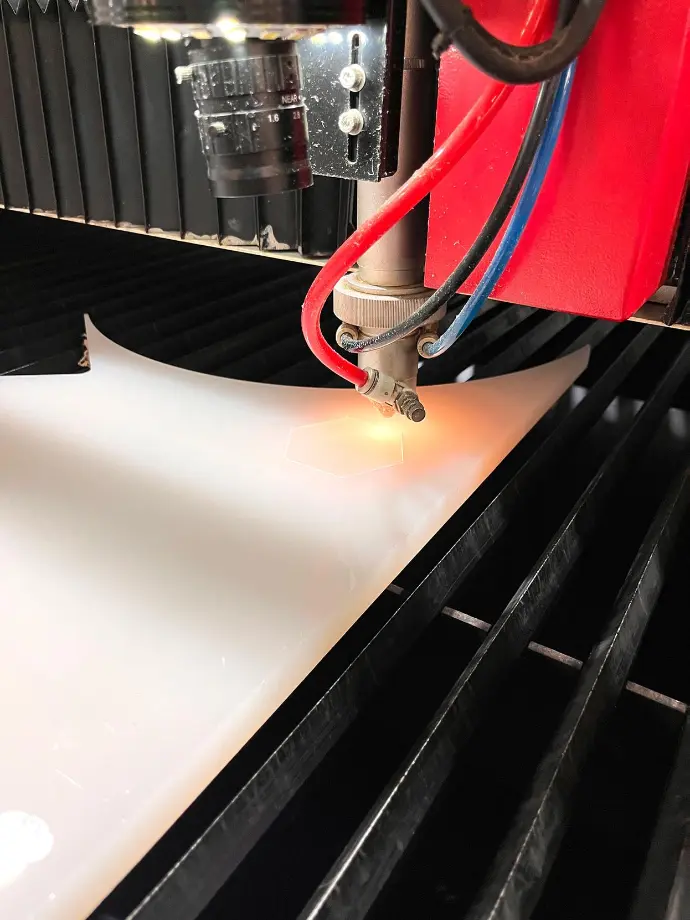

At 865FabLab, our laser services deliver sharp, clean, high-definition cuts and engravings across materials such as acrylic, wood, plastics, rubber, and more. With multiple laser systems under our roof — including high-power 300 W and medium-power 150 W CO₂ units — we offer flexible capacity, speed, and precision to suit small jobs and large panels alike.

What We Offer

- Vector cutting and outline profiling

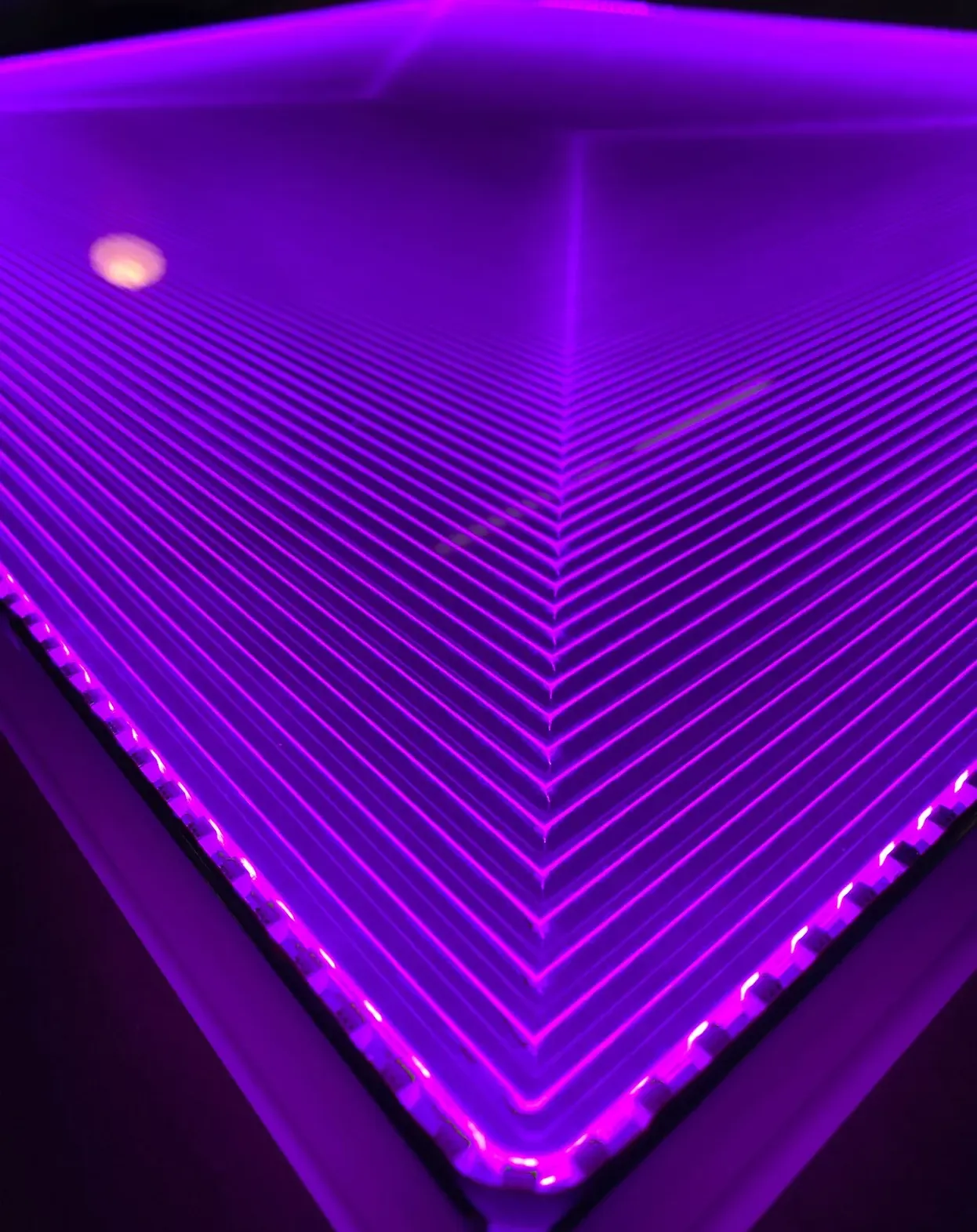

- Engraving and etching detailed artwork

- Raster photo engraving

- Kiss-cut, perforation, and selective marking

- Registration-based print‑to‑cut alignment (for cut‑after-print workflows)

- Multi-pass cutting for thicker materials

- Nesting and layout optimization for efficient sheet usage

How It Works

- Send us your artwork or cut file (or we can assist with preparation)

- Select material and thickness — we’ll advise based on what your design requires

- Approve a test cut or small example (for complex jobs)

- We process via the appropriate laser unit (150 W or 300 W), applying multi-pass or advanced strategies if needed

- Post-process finishing — clean up, detritus removal, edge polishing if needed

- Pickup or ship — protected and packaged

Materials We Work With

Our laser systems can cut, engrave, or mark:

Acrylic (clear, colored, mirrored)

Wood, plywood, MDF, veneer

Plastics: ABS, PETG, HDPE, HIPS

Rubber, gasket materials, foam sheets

Paperboard, carton, cardboard

Leather, textiles, felt

Thin aluminum composite panels (ACM) — selective cutting / marking

Fiberboard, compact board, laminates

Laser System Capabilities & Specs

Here is what each class of laser system can handle:

Class / Power Approx. Work Area Typical Material Cutting Thickness Key Strengths High-power (300 W CO₂) ~4' × 8' (48" × 96") Acrylic up to ~25 mm, wood up to ~20 mm, plastics, rubber, foam board High throughput, deep cuts, ideal for thick panels Mid-power (150 W CO₂) ~60" × 40" or similar Acrylic, wood, plastics — thinner sections, fine detail High resolution engraving, thinner materials, cleaner cut edges

Other system features in our laser lineup include:

- Precise linear guide rails and rigid frame design (for stability, accuracy, and repeatability)

- Sealed CO₂ laser tubes operating at 10.6 µm wavelength

- Automatic or assisted focusing heads (especially helpful on uneven surfaces)

- Camera or optical registration systems for print‑to‑cut workflows and alignment

- Multi-zone heating and multi-pass strategies for thicker or heat-sensitive materials

- Support for a wide range of formats (DXF, AI, SVG, BMP, etc.)

These capabilities are comparable to the features offered in the Laguna SmartShop LCB line, which supports rigid frame builds, hi‑win rails, and compatibility with wood, acrylic, MDF, ABS, rubber, and more (Laguna Tools).

CNC Laser Cutting FAQ's

Using our 300 W CO₂ system, we can cut thick acrylic and wood panels in the range of 20–25 mm (in ideal conditions). For the 150 W system, performance is optimized at thinner materials and for finer engraving.

Yes — we have camera registration systems to align printed graphics and ensure the cut matches the artwork precisely.

Yes — if the material is flat, clean, and stable, we can cut or engrave client-provided sheets as long as they are compatible with CO₂ lasers.

We accept files like DXF, SVG, AI, PDF, BMP, and raster bitmaps. If needed, we assist with file cleanup and optimization.

Yes — depending on the material, we can do light sanding, flame polishing for acrylic, or edge smoothing as part of the service.

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.