PET Acoustic Panel Cutting Services

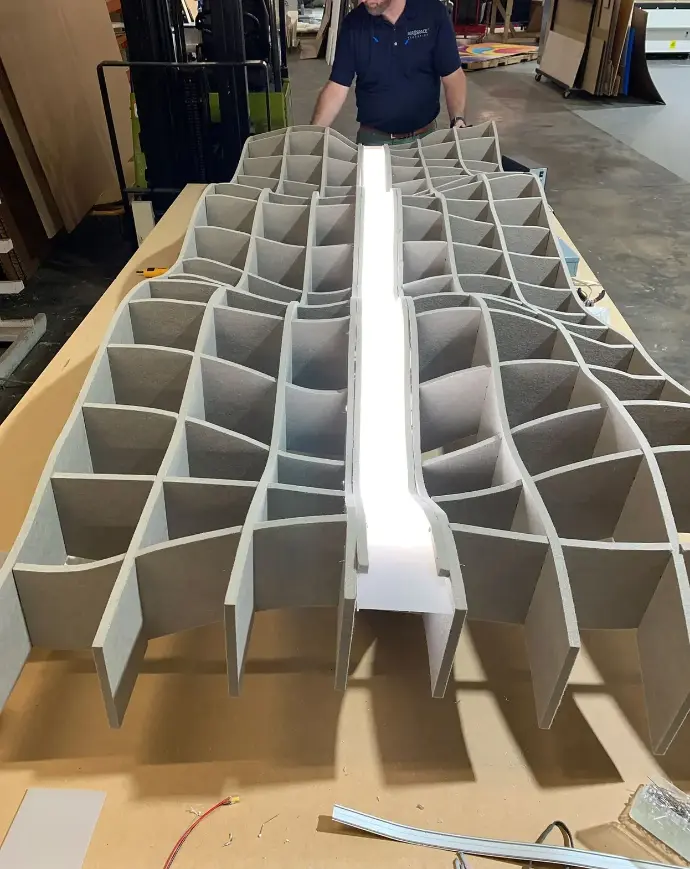

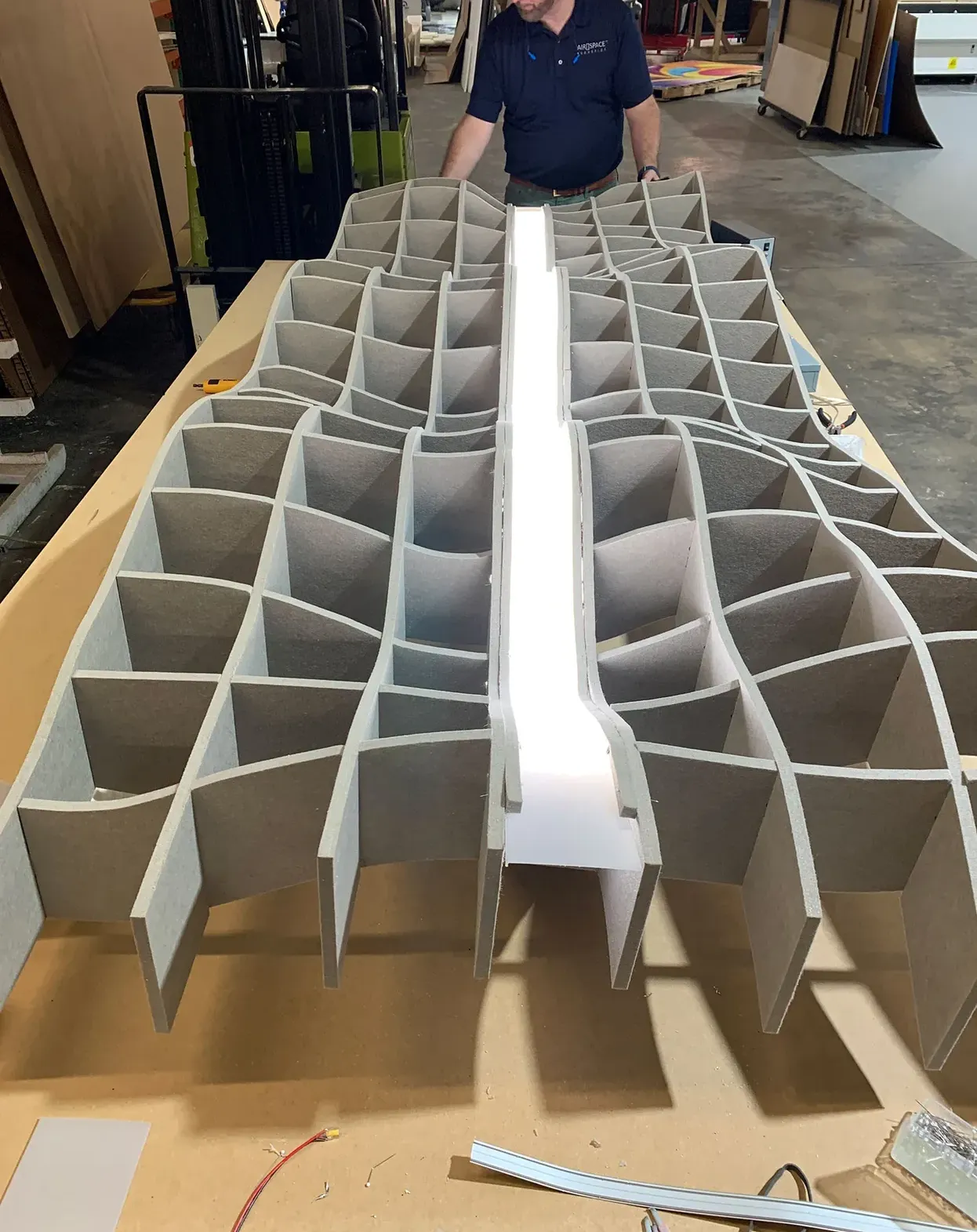

Convert PET panels into shaped baffles, branded sound features, and lighting-ready displays.

PET panels into shaped baffles, branded sound features, and lighting-ready displays.

We cut, V-groove, and finish PET acoustic material using our high-precision Kimla Veyron CNC system. Whether you need folded wall features, printed panel kits, or acoustic signage, we can deliver production-ready results.

Advanced Digital Cutting for PET Felt Panels

- Work Area: 84” × 132”

- Max Cutting Thickness: 1.5 inches

- Tooling: Oscillating knife, drag knife, V-cut, creasing wheel

- Camera Registration: For printed PET designs

- Repeatability: ±0.1 mm

- Output: Single units or production runs

- File Support: DXF, SVG, AI

Fabrication Services Offered

- Contour cutting and custom shape profiling

- V-grooving and foldable forms

- Creasing for suspended baffles and partitions

- LED integration for illuminated acoustic elements

- 3D-printed clips and brackets

- Adhesive prep and field assembly kits

Ideal Use Cases

PET acoustic panels

Decorative acoustic panels

Formable acoustic panels

Acoustic room dividers

Ceiling acoustic baffles

Cut-to-size PET panels

Custom acoustic panel cutting

Decorative soundproof panels

Fabric acoustic panels

Felt wall tiles

Acoustic ceiling cloud panels

Sustainable acoustic solutions

Acoustic design elements

Quiet interior design

Foam Cutting FAQ's

We cut a wide range of PET felt and acoustic panels, including sheets from Kirei®, Autex™, and generic recycled PET felt brands. We can also work with printed or pre-finished acoustic panels.

Yes. Our CNC system supports V-groove cutting, allowing panels to be folded into geometric shapes, ceiling baffles, freestanding forms, and display structures.

Yes. Our machine includes a camera registration system, allowing us to precisely align cuts to printed graphics or patterns on your PET panels.

We accept DXF, SVG, AI, and PDF files. If you need help preparing cut files, our team can assist with layout and optimization for your panel size and design intent.

Yes. We offer pre-applied adhesives, CNC-drilled mounting holes, and custom hardware prep. We also fabricate 3D-printed mounting clips and integrate LED lighting when needed.

We can cut PET panels up to 1.5 inches thick, depending on density and design. Multi-pass cutting is used for layered or rigid composites.

We offer both one-off prototypes and production-scale batch cutting. Whether you need a single feature panel or 200 ceiling baffles, we can scale to your project.

Yes. We ship nationwide and can package your panels with protective foam, labels, and instructions. We also offer field-assembly kits with fold lines or mounting instructions.

Absolutely. We specialize in hybrid acoustic builds — combining PET with LED lighting, acrylic, and branded elements for retail and architectural applications.

While we are primarily a service provider, we do offer raw materials including PET felt, Reboard, acrylic, and more. Visit shop.865fablab.com to browse available materials.