Custom LED Lighting for the Olli Autonomous Vehicle

A Smart Lighting Solution for an Innovative EV

When Local Motors developed the Olli — a fully autonomous, 3D-printed electric shuttle — they needed a lighting system that would complement the vehicle’s modern design and functional requirements. Their team approached 865FabLab with a complex challenge: to design and manufacture a long, curved, waterproof, and low-profile lighting fixture that would integrate seamlessly into Olli’s body.

Meeting the Challenge

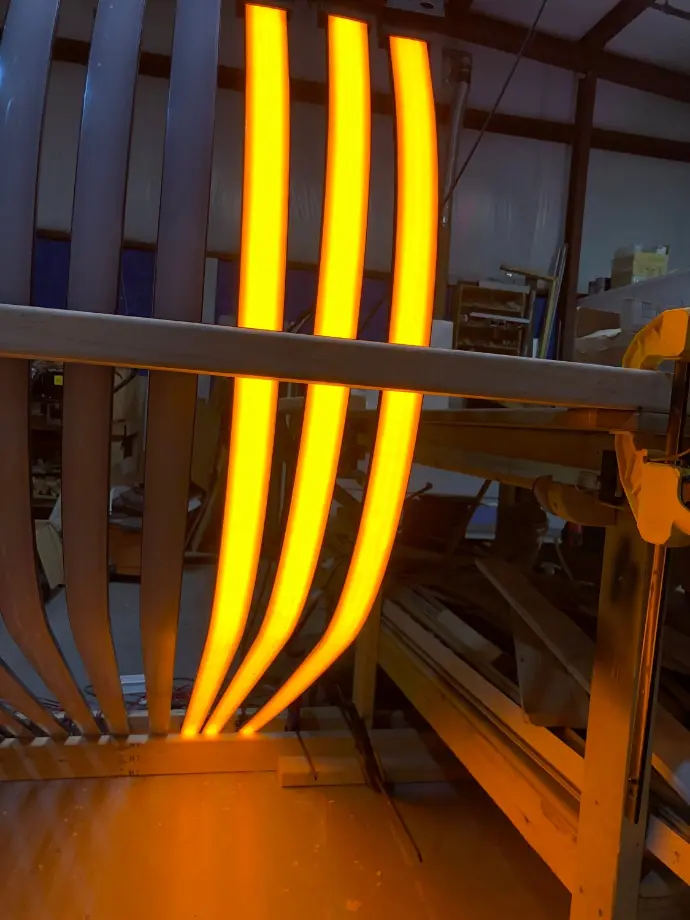

Our solution centered around the SLW10 LED channel, a sleek aluminum profile typically used for architectural applications. Using our in-house metal forming equipment, we precisely rolled the channel to match Olli’s curved exterior lines.

Inside the custom-formed housing, we installed three rows of amber LED strip, bonded using our specialized adhesive systems. The entire assembly was then filled with a specially formulated LED resin, which provided:

Complete waterproofing and environmental sealing

A homogeneous, continuous light diffusion

Structural reinforcement and vibration resistance

To complete the design, we 3D-printed custom end caps from high-strength nylon, ensuring precise fitment and long-term durability.

Where It Was Used

The Olli shuttle featured:

Two long curved light fixtures on the front

Two smaller fixtures below the bumper

Ambient LED lighting under the cabin seating and interior panels

Integrated Expertise

This project was an excellent combination of our adhesive knowledge, metal forming capabilities, LED lighting experience, and LED resin casting expertise — all working together to deliver a robust and visually cohesive lighting solution.

A Valuable Experience

Although Local Motors closed its doors in 2022, the Olli project remains an important milestone for our team. It gave us valuable experience in developing custom lighting fixtures for EV and mobility applications and strengthened our foundation in automotive-grade prototyping.

At 865FabLab, we continue to apply these integrated fabrication skills to new projects in lighting, design, and advanced product development.

Learn More:

https://www.perronerobotics.com/tony-olli

https://www.robotics247.com/article/local_motors_developer_of_olli_autonomous_shuttle_shuts_down

Key Materials & Techniques Used

(Sidebar module – HubSpot Clean Theme)

Aluminum LED Channel: SLW10 surface-mount profile

LED Type: 12V amber LED strip (triple-row configuration)

Adhesives: High-performance bonding system for aluminum and plastic interfaces

Encapsulation: Custom-formulated LED resin for optical clarity and waterproofing

End Caps: 3D-printed nylon components (high-strength polymer)

Forming Method: CNC-guided roller bending for curved light profiles

Finish: Continuous, diffused amber illumination