Pre-Made Vacuum Formed Molding Kits for Retail Window Displays

Project Overview

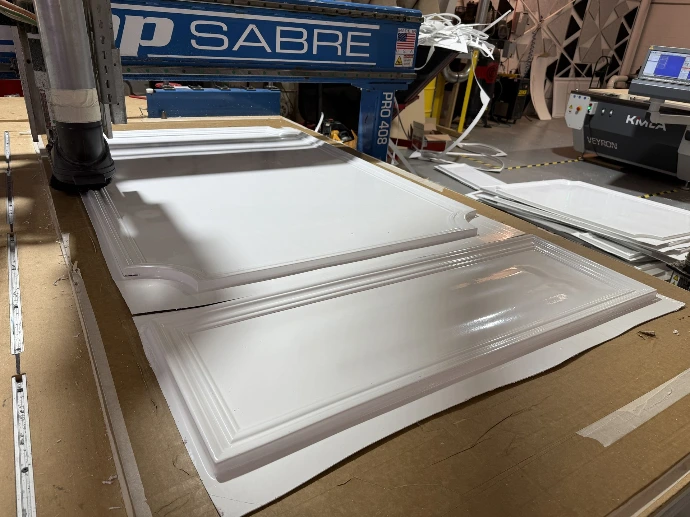

This project focused on the development of pre-made vacuum formed wall molding kits for a multi-location retail customer.

The molding kits were designed for window display installations and shipped directly to individual store locations, ready for fast and consistent installation.

Originally, the customer planned to purchase standard wall molding and corner pieces from Home Depot and complete all cutting, mitering, and assembly work independently in each store. After reviewing material costs, labor time, and the risk of inconsistent results, it became clear that a custom molding kit solution offered a significantly more efficient and scalable approach.Start writing here...

Design Challenge

Retail window displays demand:

Consistent appearance across all locations

Fast installation with minimal skilled labor

Clean corners without complex miter cuts

Lightweight, durable materials suitable for repeated seasonal changes

Traditional wall molding installation requires precise measuring, difficult miter cuts, and on-site adjustments—especially problematic when scaled across multiple stores.

Materials & Manufacturing

To balance strength, weight, and cost efficiency, the project combined multiple fabrication methods:

Vacuum formed panels for shaped molding sections

XPS foam straight lengths CNC-cut for lightweight linear sections

Modular sizing to suit different window display layouts

Vacuum forming allowed us to replicate complex molding shapes at scale while maintaining tight dimensional consistency—ideal for branded retail rollouts.

Production & Distribution

Panels were produced in batches and packaged as store-ready kits, then shipped directly to each retail location. This approach eliminated:

Store-level fabrication work

Skilled labor requirements

Inconsistent results between installations

Each store received the same components, ensuring a uniform appearance across the entire retail network.

Cost & Efficiency Benefits

Compared to sourcing individual molding pieces and performing on-site assembly, the vacuum formed molding kits delivered clear advantages:

Lower total material cost

Reduced installation labor

No miter cutting or fitting errors

Faster store setup times

Improved visual consistency

For the customer, the decision became straightforward once labor, waste, and time were factored in.

Applications

While developed for retail window displays, this solution is also well suited to:

Decorative wall molding in commercial interiors

Pop-up retail displays

Cosmetics and liquor brand installations

Temporary architectural features

Event and seasonal merchandising displays

The modular nature of the kits makes them adaptable across multiple industries.

Why This Project Matters

This case study highlights how custom fabrication can outperform off-the-shelf solutions when projects scale across locations.

By combining:

Vacuum forming expertise

CNC machining

Material optimization

Display and signage industry experience

865 Fab Lab delivered a solution that reduced cost, simplified installation, and improved overall quality.

Looking for Custom Wall Molding or Display Kits?

If you’re planning a project involving custom wall molding kits, decorative wall panels, or retail display fabrication, our team can design and manufacture a solution tailored to your rollout needs.

Contact 865 Fab Lab to discuss your project requirements.